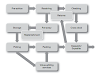

The system needs to ensure that each group of stores has similar volumes where possible.

Depending on daily volumes, staff can increase or decrease the number of locations (stores) that they look after. Large-volume stores may be situated in a number of different zones with the totes/containers being consolidated at the despatch area.

• Individual

product lines required by the stores will be picked in bulk and

transferred to the correct operator station by cart, pallet truck or via a conveyor. Each store will have a tote or totes assigned to it.

transferred to the correct operator station by cart, pallet truck or via a conveyor. Each store will have a tote or totes assigned to it.

• Once

the SKU has arrived at the ‘put’ station the operator scans each item anda

flashing light displays at each location indicating which containers (relating

to a particular store) require that product and how many items are required.

to a particular store) require that product and how many items are required.

Confirmed ‘put’ results are uploaded to the system in real

time to update the WMS

0 Comments